There are a

lot of different brands of mold material, each with different

properties and costs. They all basically work the same. I use

smooth-on because they were in the right place at the right time

for me. Thanks, Francis Lestingi. Do not consider my use of this

product line as an endorsement.....but it does work.

You need to first start with a level work surface and a model.

In this case, I have a small (aprox 3" wide) wood carving of a

Nantucket basket. It is sealed with a lacquer sanding sealer and

two coats of high gloss lacquer. The mold rubber is very

aggressive so the pattern must be coated with a parting agent. I

first apply 2 coats Butchers Wax. Let each coat dry thoroughly

and buff.

Here's what you need.....

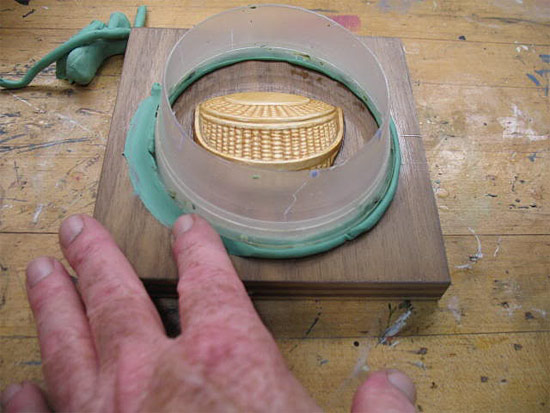

Next I need to form a containment for the mold....in this case,

I just cut out the bottom of a deli container. Next I roll out a

"snake" with modeling clay (it can't contain sulfur) and apply

it to the rim of the container.

I then center it around the pattern and press it down which

pushes the clay to both the inside and outside of the

container....

and spread it smooth with a finger.....both inside and outside.

. .

|

|

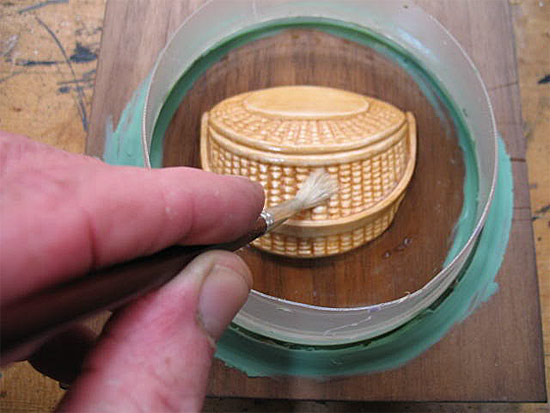

Next I

spray on another parting agent and brush it around to be sure

all surfaces are covered.

Let dry for 10 minutes. Then spray another light coat and let it

dry.

Next, mix equal parts of the mold rubber and stir completely (in

this case a half cup each)...the two parts are different colors,

so mix till it's consistently blue.

Now, I pour in about 20% of the rubber and tip the mold so that

the rubber flows around the entire model.....this will prevent

air bubbles from forming in tight places.

Then pour in the rest. To remove any remaining bubbles I just

tap the base of the mold with a rubber mallet for about 4 or 5

minutes.....or till the bubbles stop surfacing.

The rubber cures in about 6-8 hours.

If everything was done right.....Please God....please.....you

have a perfect mold of the original casting. (The prayer was for

this to work cause, if it doesn't.....you could loose the mold

AND the pattern)

WHEW!!!!!

![[Smile]](http://www.letterville.com/ubb/smile.gif)

|

|

Casting.....

Here's the two part plastic....I get the best deal on this stuff

at Dick Blick (about $20....and I'll get about 50 castings).

You'll also need a mixing cup and two small measuring cups and a

popsicle stick for stirring.

Spray the mold with the release agent and let dry for 5

minutes.....don't over spray and don't spray anywhere near where

you will be painting.....boy, ya wanna see fisheye????

![[Rolling On The Floor]](http://www.letterville.com/ubb/graemlins/rolf.gif)

Mix equal parts of part A and B....Thoroughly!!!!!for about a

minute (it'll start to feel warm) then pour it in starting at

the lowest point. Hey, if you are gonna pour one.....why not

two?

![[Smile]](http://www.letterville.com/ubb/smile.gif)

It will start to "bloom" in the deep areas first.

Stuff cures in about 15 minutes (it's still soft so place it on

something flat for a while).

Before you can paint it, you must clean off the parting

agent....I wash first in terps and then isopropal alcohol

(rubbing alcohol). This plastic is not UV safe so I spray a coat

of Krylon Fusion then size and gild.

Bingo......Instant BLING$$$$$

I'm happy that some will put this sxs to good use.

Happy Molding and Casting!

Joe,

|

|

Joe Cieslowski

Email Joe

|