|

Here's

my step by step on doing with software what I used to do with

compass and straight edge.

To do this construction, you will need precise measurements of

the width of the sign, the shoulder height to the start of the

curve, and the height to the top middle of the sign. With these

three measurements, you can construct an accurate radius. You

are still doing this at your own risk because the other company

may have produced this with flat spots as Dale mentioned.

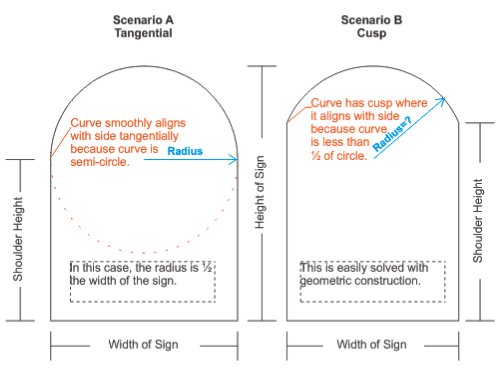

Below are two scenarios, assuming each one is a true arc. One is

actually a semi circle on top of the sign that ends tangentially

with the sides, the other is a section of circle with cusps

where it intersects the sides of the sign.

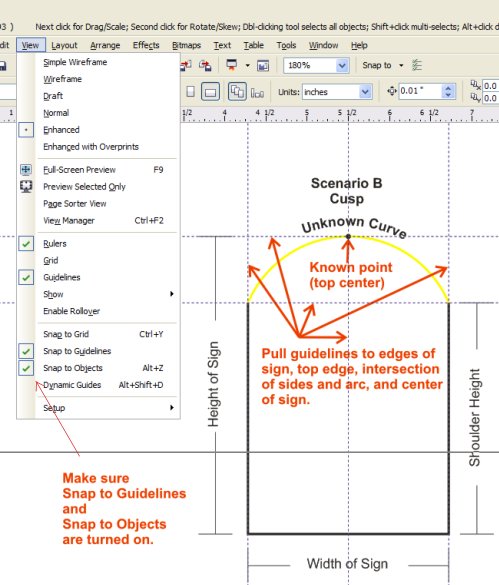

This is how I set up my workspace.

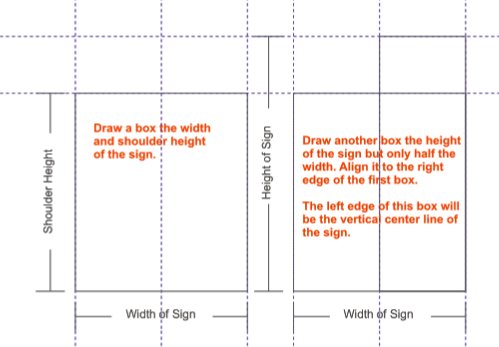

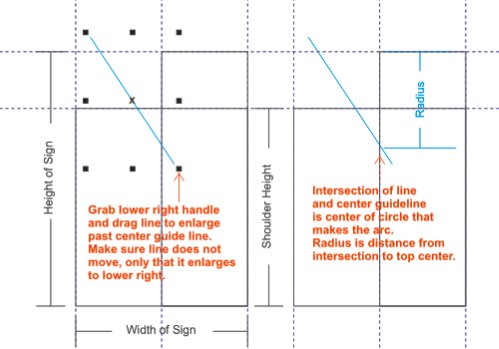

I draw two boxes in scale, one the size of the rectangular

portion of the sign, the other the total height of the sign but

half the width.

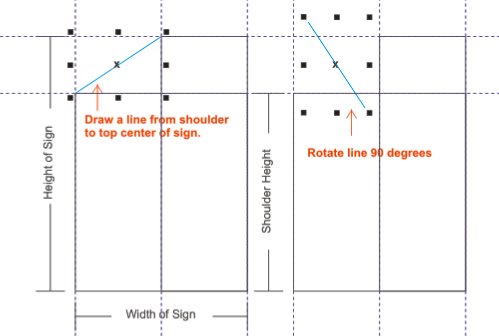

Draw a line and rotate it 90 degrees. Make sure it snaps exactly

at the shoulder and top center.

Drag the line larger until it intersects the center line of the

sign.

The intersection point is the center of the circle that will

make the arc section.

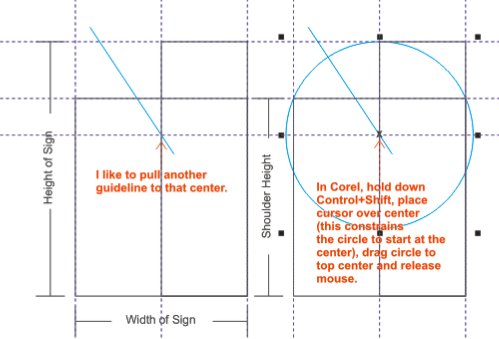

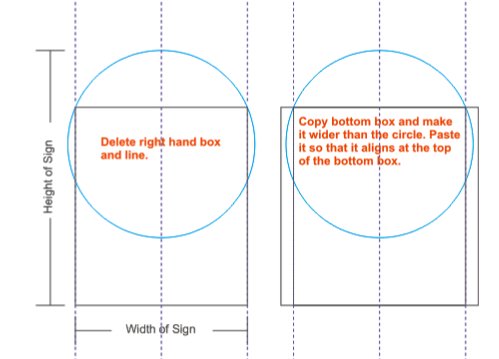

Start the editing process.

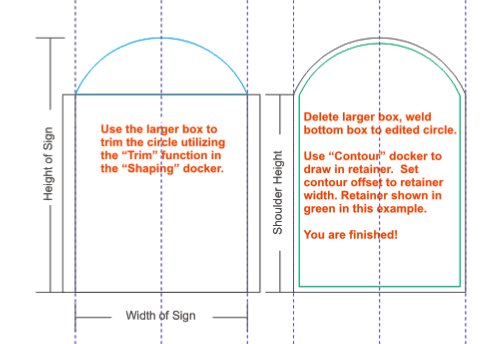

Finish trimming, welding, and adding the retainer contour.

I'd superimpose this over a minimally distorted photo of the

sign to check and see if there's any obvious anomalies. Also, on

installation, bring a router or laminate trimmer with a flush

cutting bit with a bearing on it. If the face is slightly large,

the router will trim it to match the can. Be sure to allow for

expansion clearance.

Even with measurements, it is necessary to generate some

computer files for production, permitting, etc. The steps above

will help to get things very close to actual and also to verify.

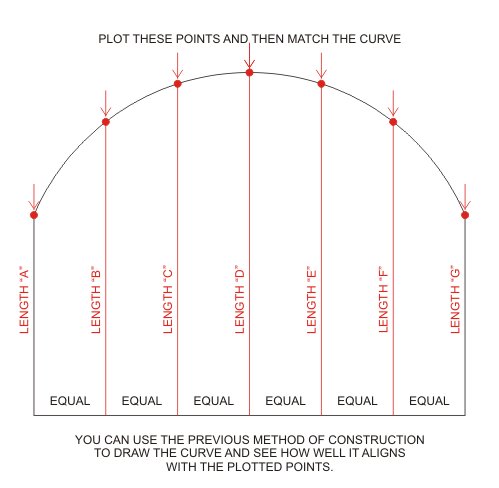

I've field measured numerous odd shaped faces for retrofit,

including many Granite ones. I'll set up my measurements similar

to what I show below.

I'll plot the measurements in Corel and then generate a curve to

match.

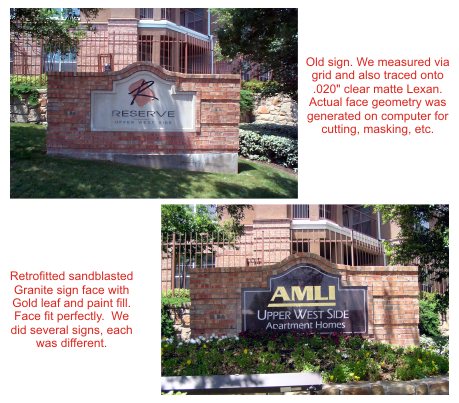

For really weird shapes, I have a piece of matte .020" clear

Lexan, approximately 4' x 10'. I'll hold that up against the

face and mark everything on it with a pencil. I then precisely

measure that clear template and plot it on the computer. When my

Lexan template is not being used, it gets rolled up and secured

with tape.

Following is a picture of a retrofit we did using measurements,

photos with minimal distortion, traced pattern on Lexan, and

computer generation.

|