Well to

install bubble free vinyl on any surface there are very important thing

you must do first. Surface prep is very important. If there is any

possibility that there can be

any grease or wax on your material I recommended a

good degreaser I use Rapid Prep for this. After the degreasing I re

clean use the Rapid TacII. when you do this cleaning you should use a

unprinted white paper towels and do not go over the area that you

already cleaned with the already used paper towel as you can

contaminate. The surface should be lint and dust free as any of this

lint/dust can create bubbles and the vinyl can trap the dust under it

and cannot be removed.

A good squeegee free of nicks as vitally important. I used the 3M gold

squeegees and on one end I place the fuzzy side of velcro for installing

digital printed graphics and this eliminates the scratching of the

printed graphics or even eliminating the little scratches on the cut

graphics then you re squeegee.

A sharp squeegee free of

nicks is very important as these nicks can be the biggest culprit of

bubbles. The edge must be smooth and the best way I have found is to

sharpen your squeegee. You can do this by rubbing the edge at an angle

on another squeegee in a back and forth motion. Working both sides of

the edge till you get a smooth nick free edge.

To do a banner the first

thing I do after the cleaning it to tape the banner down to the table so

that is does not move under the graphics, that would create installation

problems. Measure and place the graphics to the banner according to your

layout. I will be showing you how to do two kinds of hinges, a top hinge

and a side hinge. Also I will show you how to register a 2 color graphic

using registration marks.

TOP HINGE

After the graphics have been

taped into place along the top edge we can now begin to install the

graphics.

On a long line

of copy with large letters I cut apart the letters for more manageable

pieces.

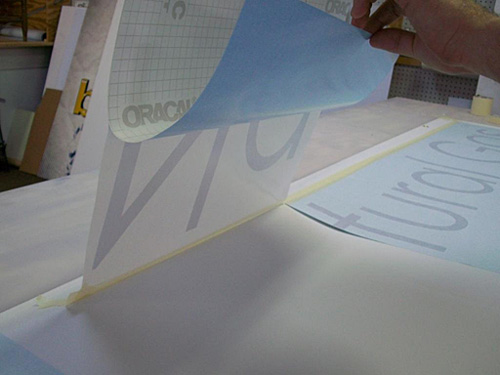

To begin you

start by removing the backer from the transfer tape, pulling it only

half way down creating a kind of bridge to hold and keep the vinyl from

touching the banner until you are ready to squeegee. Remember that the

vinyl is pressure sensitive and will bond with and pressure that

includes if it touches the banner and you try and pull it off.

OK now when you

begin to squeegee start of course at the top and squeegee into the

graphics holding the pulling horizontal but holding the squeegee at an

angle so when you are pushing or pulling the squeegee you will be

pushing the air to the bottom of the graphic not towards the area that

you already applied. This is very important motion as this is one of the

ways to trap the air having the wrong squeegee angle. I firm pressure is

very important...a wimpy squeegee pressure will cause trapped air as

well.

SIDE HINGE

Side hinge is another way to

install long graphics that you cannot or do not want to cut apart into

smaller pieces. Now a way to help with the placement of the graphics we

use a registration mark.

I use a piece of tape and mark a

line across the graphics onto the tape. So when you lift the graphic to

begin removing the backer you have a reference to reposition the graphic

straight. Also notice the triangle in the circle logo...I will talk more

about this registration mark.

Again the backer

becomes the bridge to keep the graphics held off the banner until you

squeegee them.

REGISTRATION MARKS

When you have a 2

color job and have a tight registration try using triangle to help in

the placement of the multiple graphics. The first color you lay down

should have the triangles in place on the material when you apply the

graphics. The second layer you carefully cut the triangles to reveal the

triangles below like a window to align the triangle up. Tape into place

and install with a top hinge.

So there you go bubble free install of pressure

sensitive graphics on a banner.

|